34

Introduction to the Process and Application Fields of Circular Knife Die Cutting Machine

2023/3/9

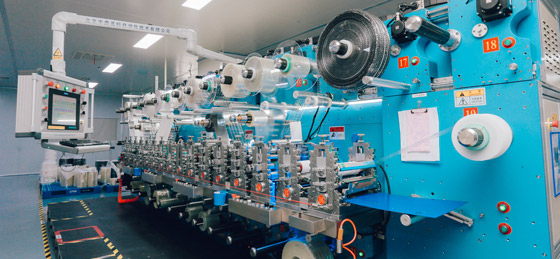

The die-cutting process is a commonly used process for packaging printed products, which is to use a die-cutting knife to assemble a die-cutting plate according to the design requirements of the product. Under the action of pressure, the printed product or other plate-like blanks are rolled and cut into the desired shape or cut marks. The indentation process of a die-cutting machine is to use a wire cutter or wire mold, and then use pressure to press out wire marks on the sheet metal, or use a rolling wheel to bend and shape the sheet according to a predetermined position. The usual die-cutting and indentation process for this equipment is to combine the die-cutting knife and the indentation knife into the same template, and simultaneously perform die-cutting and indentation processing on the die-cutting machine, abbreviated as die-cutting.

The process of the die-cutting machine: The main process of the indentation of the equipment is plate loading → pressure adjustment → moment determination → pasting of substrate and auxiliary materials → pressure testing die-cutting → formal die-cutting indentation → waste removal → finished product winding or cutting into pieces → counting and packaging. The die-cutting process of equipment has also been increasingly favored and valued by printing enterprises, as it has adapted to the requirements of mechanization, linkage, and automation in future post-press processing technology. This allows people to connect the die-cutting mechanism and printing machinery into a production line as needed, and achieve online operation. It can also effectively reduce labor demand, shorten process flow, and reduce losses in the process, This can improve production efficiency, reduce labor costs, and obtain greater profits.

Under the current market situation, die-cutting machines are mainly used in fields such as packaging, automobiles, computers, mobile phones, cameras, etc.

1. Application of adhesive products: die-cutting of various adhesive products, such as electronic and electrical special rubber pads, silicone stickers, Velcro, and other die-cutting needs in the automotive and electronic industries.

2. Application of dustproof materials: die-cutting requirements for cosmetic cotton, filter cotton, dustproof mesh, and non-woven fabrics.

3. Application of shockproof products: demand for rebound rubber pads, rubber, flame retardant EVA, and high foaming die-cutting.

4. Application of insulation material I: die-cutting requirements for fire-resistant fast paper, PVC, PET, kraft paper, and sponge sheaths.

5. Application of EMI shielding materials: die-cutting requirements for copper foil, aluminum foil, and conductive cloth.

6. Application of heat-resistant and thermal insulation materials: die-cutting requirements for transparent mica sheets, fiber cloth, and thermal insulation cotton.

7. Application of paper packaging materials: die-cutting requirements for corrugated paper, packaging paper, and cardboard.

The process of the die-cutting machine: The main process of the indentation of the equipment is plate loading → pressure adjustment → moment determination → pasting of substrate and auxiliary materials → pressure testing die-cutting → formal die-cutting indentation → waste removal → finished product winding or cutting into pieces → counting and packaging. The die-cutting process of equipment has also been increasingly favored and valued by printing enterprises, as it has adapted to the requirements of mechanization, linkage, and automation in future post-press processing technology. This allows people to connect the die-cutting mechanism and printing machinery into a production line as needed, and achieve online operation. It can also effectively reduce labor demand, shorten process flow, and reduce losses in the process, This can improve production efficiency, reduce labor costs, and obtain greater profits.

Under the current market situation, die-cutting machines are mainly used in fields such as packaging, automobiles, computers, mobile phones, cameras, etc.

1. Application of adhesive products: die-cutting of various adhesive products, such as electronic and electrical special rubber pads, silicone stickers, Velcro, and other die-cutting needs in the automotive and electronic industries.

2. Application of dustproof materials: die-cutting requirements for cosmetic cotton, filter cotton, dustproof mesh, and non-woven fabrics.

3. Application of shockproof products: demand for rebound rubber pads, rubber, flame retardant EVA, and high foaming die-cutting.

4. Application of insulation material I: die-cutting requirements for fire-resistant fast paper, PVC, PET, kraft paper, and sponge sheaths.

5. Application of EMI shielding materials: die-cutting requirements for copper foil, aluminum foil, and conductive cloth.

6. Application of heat-resistant and thermal insulation materials: die-cutting requirements for transparent mica sheets, fiber cloth, and thermal insulation cotton.

7. Application of paper packaging materials: die-cutting requirements for corrugated paper, packaging paper, and cardboard.

Anhui E-cloud Photoelectronic technology Co,.Ltd Copyright 皖ICP备18008606号-1 {Disclaimers}